Equipment status

PU Molding LINE

– T/TABLE/High-Pressure Foaming Machine/ROBOT

– T/TABLE/Low-Pressure Foaming Machine/ROBOT

– BATCH High-Pressure Foaming Machine

Foaming machines are primarily used in the process of manufacturing polyurethane (PU) foam, playing a key role in the precise mixing of raw materials and the formation of high-quality foam. Equipped with automated control systems, they adjust the mixing ratio, temperature, and pressure of raw materials in real time to consistently maintain the quality of the foam.

Scroll left and right.

| Equipment Name | Specifications | Quantity | Purpose |

|---|---|---|---|

| T/TABLE/High-Pressure Foaming Machine/ROBOT | (350g/sec)_8M, 10M,11M | 25 | For Soft/Hard Use |

| T/TABLE/Low-Pressure Foaming Machine/ROBOT | 120g/sec | 3 | For Soft Use |

| BATCH High-Pressure Foaming Machine | 400/sec | 3 | For Soft/Hard Use |

PU Molding LINE

Thomson Press

The Thompson Press is a hydraulic press machine used for shaping and cutting materials such as foam, felt, sponge, and automotive mats. This equipment operates by placing the workpiece on the worktable, which moves horizontally back and forth. Once the transfer table is positioned accurately, the press performs vertical strokes to complete the shaping process.

Scroll left and right.

| Equipment Name | Specifications | Quantity | Purpose |

|---|---|---|---|

| Thomson Press | Hydraulic | 2 | For Product Trimming |

FELT Molding LINE

Preheating Plate Machine

The Press Preheating Plate Machine is equipment designed to evenly heat thermoplastic materials such as PET, optimizing the quality of the molding process. This machine enables precise molding through uniform temperature distribution.

Scroll left and right.

| Equipment Name | Specifications | Quantity | Purpose |

|---|---|---|---|

| Preheating Plate Machine | W: 1400 L:1600 H: 1200 | 3 | Material Heating and Uniformity, Improving Molding Quality |

FELT Molding LINE

Hot-Air Oven Machine

The Hot-Air Oven Machine is equipped with a precise temperature control system, allowing it to set appropriate temperatures based on the melting point and deformation potential of PET felt. This enables heating while maintaining the desired physical properties. In addition to heating PET felt, the hot-air oven can be used for heating and drying various materials, and it can be custom-designed to suit specific applications. It can also be tailored based on the thickness, density, and desired processing conditions of the felt.

Scroll left and right.

| Equipment Name | Specifications | Quantity | Purpose |

|---|---|---|---|

| Hot-Air Oven Machine | Width: 2M, Length: 14M Top: Ceramic Heater, Bottom: Rod Heater | 2 | Material Heating and Uniformity, Improving Molding Quality |

FELT Molding LINE

Press

The Molding Press is equipment designed to transform various felt materials into desired shapes by applying pressure to the material, enabling the creation of complex shapes while maintaining high precision, even in mass production. The Trim Press is used to complete products by performing hole piercing and edge cutting on molded parts. It precisely trims excess material or flash generated during the molding process, refining the dimensions and surface of the components.

Scroll left and right.

| Equipment Name | Specifications | Quantity | Purpose |

|---|---|---|---|

| Press | 150 TON, 200 TON, 300 TON, 500 TON | 13 | Molding, Trimming |

Other Post-Process Equipment

Ultrasonic Welding Machine

The Ultrasonic Welding Machine is equipment that utilizes high-frequency ultrasonic vibrations to join components made of thermoplastic materials. It is commonly used in the manufacturing of automotive parts, particularly components like wheel guards. This machine generates localized frictional heat at the joining area through ultrasonic vibrations, enabling the precise and high-speed welding of two plastic parts.

Scroll left and right.

| Equipment Name | Specifications | Quantity | Purpose |

|---|---|---|---|

| Ultrasonic Welding Machine | Handgun | 6 | Point Welding |

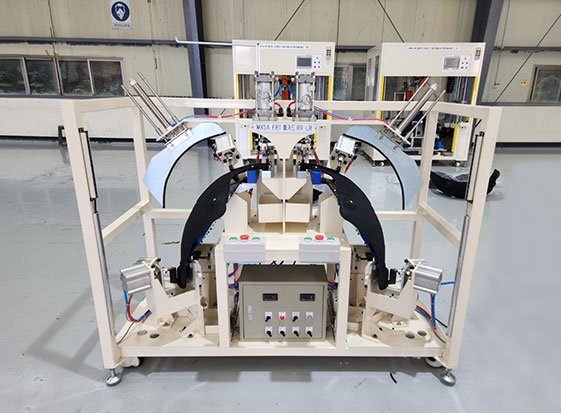

Other Post-Process Equipment

Piercing Jig

The Piercing Jig is equipment used to assist in creating precise holes in specific locations after the felt molding foam process is completed. This jig minimizes errors that may occur during operation by providing accurate position control and securing components. It is designed to repeatedly process shapes such as assembly points, slots, and grooves at precise locations.

Scroll left and right.

| Equipment Name | Specifications | Quantity | Purpose |

|---|---|---|---|

| Piercing Jig | - | 5 | Side Hole Cutting |

Other Post-Process Equipment

Seam Welding Machine

The Seam Welding Machine (Seam Welder) is equipment used in the post-processing of automotive parts, such as wheel guards, to precisely join two sections of a component. This machine is primarily used to weld thermoplastic felt components by applying uniform heat and pressure to the seams, creating strong and durable bonds. As a result, it enhances the bond strength between parts, improves durability, and provides a smooth and consistent finish to the exterior.

Scroll left and right.

| Equipment Name | Specifications | Quantity | Purpose |

|---|---|---|---|

| Seam Welding Machine | - | 1 | Seaming, Welding |

TOP

Skip to main content

TOP

Skip to main content